Electrical Engineering Services

Delivering first-rate electronics design and engineering is essential for achieving a high-performing final product. As a certified engineer at the forefront of innovative design, I offer expertise in circuit board design, electronic circuit design, and other custom solutions, all at cost-effective rates. My services cover the entire process, from prototype to final production, ensuring timely market readiness for your business. My clients trust me to deliver cutting-edge, reliable designs that stand out in the market.

Circuit Board and Electronic Circuit Design

Specializing in electronic design, I provide high-quality circuit board and electronic circuit design that excel in performance. From schematic diagrams to PCB layout design, I ensure an unprecedented level of detail in every aspect of the design phase. Whether you need a simple or cutting-edge design, you can trust me to deliver the best possible final product.

I utilize advanced analysis tools and skills to mitigate risks and solve complex problems, from sophisticated material selection to addressing thermal or vibration concerns. By analyzing your specific needs and requirements, I deliver products that excel in the competitive tech environment. My engineering solutions include:

- Schematic Design & Digitization

- Custom Components Library Creation

- PCB Layout Design

- Firmware Development

- DFx Consultation

My engineering and design services cater to various industries, including Commercial, Industrial, Medical, Communication, and Consumer sectors. I provide a one-stop solution for product design, extending beyond design to offer first-rate electronic prototyping. This allows you to test your design with minimal capital and risk, demonstrating your product before moving to manufacturing.

Stages of Electronics Development

Developing project specifications

Developing electronics project specifications with a customer begins with an in-depth consultation to thoroughly understand their vision, requirements, and objectives. This collaborative process involves discussing the intended use of the product, target audience, desired features, and performance expectations. By asking detailed questions and actively listening to the customer’s needs, I can gather crucial information about the project’s scope, budget, and timeline. Additionally, I assess any regulatory or industry-specific standards that must be met. Using this information, I draft a comprehensive specification document that outlines the project’s technical requirements, design constraints, and deliverables. This document is then reviewed and refined in collaboration with the customer to ensure complete alignment and satisfaction. Regular communication and feedback loops are maintained throughout the project to adapt to any evolving needs or changes, ensuring a successful outcome that meets or exceeds the customer’s expectations.

Research and development R&D

The Research and Development (R&D) phase is a critical step in the electronics design process, aimed at transforming initial concepts into viable, innovative solutions. This phase begins with a thorough exploration of the project’s goals and requirements, leveraging existing technologies and identifying gaps where new advancements can be made. I conduct extensive research to evaluate different design approaches, materials, and components, considering factors like cost, performance, and reliability.

During the R&D phase, I create preliminary designs and simulations to test various hypotheses and validate theoretical models. Prototyping plays a key role here, allowing for iterative testing and refinement of designs. By building and testing prototypes, I can identify potential issues early and make necessary adjustments before moving forward. Collaboration with the customer is maintained throughout this phase to ensure the design aligns with their vision and requirements.

Selecting component base for projects

Selecting the component base for an electronics project is a crucial step that significantly influences the performance, reliability, and cost-effectiveness of the final product. This process begins by analyzing the project specifications to determine the essential requirements for each component, including electrical, thermal, and mechanical characteristics. I then conduct a comprehensive review of available components, considering factors such as quality, availability, compatibility, and future-proofing.

The selection process involves evaluating various components from multiple manufacturers to ensure the best fit for the project’s needs. Key considerations include component specifications, tolerances, power ratings, and environmental conditions they will be subjected to. Additionally, I assess the lifecycle of each component to ensure long-term availability and support, mitigating risks associated with obsolescence.

Cost-effectiveness is also a critical factor. I balance performance requirements with budget constraints, aiming to optimize the cost without compromising on quality. Vendor relationships play a role here, as strong partnerships can provide access to better pricing, technical support, and reliable supply chains.

Once potential components are identified, I perform detailed simulations and prototyping to validate their performance within the circuit design. This step helps in identifying any potential issues early, allowing for adjustments before finalizing the component list. By carefully selecting and validating each component, I ensure that the final design is robust, efficient, and ready for production, meeting both the technical and economic goals of the project.

Creating electrical schematics

Creating electrical schematics is a pivotal phase in the electronics design process, serving as the blueprint for the entire project. This phase begins with translating the project specifications and requirements into a detailed and organized diagram that visually represents the electrical connections and functions of the circuit.

Using EDA software, I meticulously arrange components such as resistors, capacitors, microcontrollers, and sensors, ensuring that each element is correctly represented with standardized symbols. Clear and consistent labeling of components and connections is essential to avoid confusion and ensure accurate interpretation by anyone reviewing the schematic.

During this process, I pay close attention to the relationships and interactions between different components. This involves defining the power supply paths, signal flow, grounding methods, and interconnections that form the circuit’s functional core. Ensuring proper placement and routing of these connections is crucial to minimize potential issues like noise, interference, and signal degradation.

I also perform preliminary analyses and simulations to validate the schematic’s functionality, checking for common errors such as incorrect connections, missing components, or incompatible parts. These simulations help in predicting the circuit’s behavior under different conditions, allowing for early identification and rectification of potential problems.

Throughout the schematic creation process, I maintain close communication with the customer to ensure alignment with their expectations and requirements. Any changes or updates are carefully documented and incorporated into the design, ensuring a transparent and collaborative development process.

The final schematic serves as a comprehensive guide for subsequent phases, including PCB layout design, prototyping, and production. By creating accurate and detailed electrical schematics, I lay the foundation for a reliable and high-performing electronic product.

Printed circuit board design

Designing and tracing printed circuit boards (PCBs) is a crucial step in bringing an electronic design to life. This process involves converting the electrical schematics into a physical layout, where components are strategically placed, and electrical traces are routed to ensure optimal performance and reliability. Key considerations include signal integrity, thermal management, and manufacturability.

For a detailed overview of the PCB design process, please visit my PCB layout service page.

Preparing design documents and manufacturing data

Preparing design documents and manufacturing data is a vital step in transitioning from design to production. This phase involves compiling all necessary documentation, including detailed schematics, PCB layouts, bill of materials (BOM), and assembly instructions. These documents ensure that the manufacturing process is smooth, accurate, and efficient, providing clear guidance for production teams.

For a detailed overview of how to prepare design documents and manufacturing data, please visit my PCB layout service page.

Manufacturing and testing product prototypes

Manufacturing and testing product prototypes is a critical phase where design concepts are transformed into tangible, functional units. I arrange for prototype manufacturing and assembly, leveraging a network of reliable partners to ensure high-quality builds. This step involves creating a small batch of prototypes that precisely reflect the design specifications, using advanced manufacturing techniques and quality materials.

Once the prototypes are assembled, rigorous testing is conducted to verify their functionality, performance, and reliability. I employ a range of testing methodologies, including functional testing, stress testing, and environmental testing, to identify any issues and ensure the prototypes meet all design and performance criteria. This thorough evaluation helps in refining the design and addressing any potential problems before moving to full-scale production.

By arranging prototype manufacturing and conducting comprehensive testing, I ensure that the final product is not only ready for market but also reliable and high-performing. This process reduces risks, optimizes design, and provides valuable insights, paving the way for successful product development and launch.

Developing product firmware

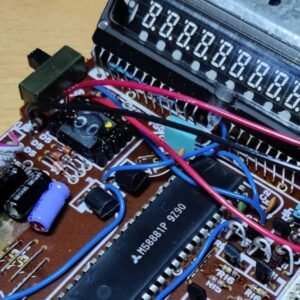

Modern electronic designs often include embedded microprocessors. Therefore, developing product firmware is an essential aspect of bringing electronic designs to life, ensuring that the hardware functions as intended. I specialize in developing firmware exclusively for products I have designed or upgraded, guaranteeing seamless integration and optimal performance. This focused approach allows me to tailor the firmware precisely to the hardware specifications, enhancing efficiency and functionality.

The firmware development process begins with a thorough understanding of the product’s requirements and functionalities. I write, test, and debug the firmware, ensuring it interacts correctly with all components and delivers the desired performance. By utilizing advanced development tools and adhering to best practices, I create robust, reliable firmware that supports the product’s operational needs.

Through my targeted firmware development services, I ensure that each product achieves its full potential. This meticulous process results in high-quality, efficient, and reliable electronic products that meet and exceed customer expectations, providing a competitive edge in the market.

Ready to bring your electronic design project to life?

Contact me today to discuss your requirements and see how my expertise can help you achieve innovative, high-quality, and reliable solutions. Whether you need circuit board design, electronic prototyping, or custom firmware development, I am here to provide the services and support you need. Let’s work together to turn your vision into reality. Get in touch now to start your project!